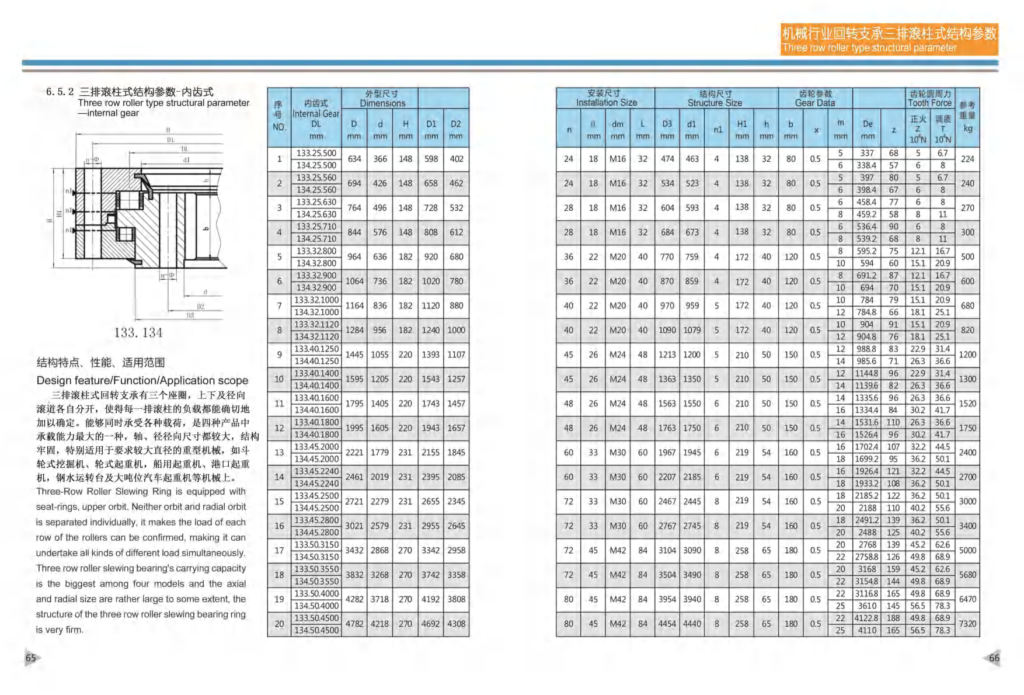

Three row roller type slewing bearing has three seat rings. The upper and lower raceways and radial raceways are separated respectively, so that the load of each row of rollers can be determined accurately. It can bear all kinds of loads at the same time. It is one of the four products with the largest bearing capacity. The shaft and radial dimensions are large and the structure is firm. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel excavator, wheel crane, marine crane, port crane, steel water transport turntable and large tonnage truck crane.

Product Detail

Three row roller slewing bearing has three seat rings, upper and lower and radial raceways are separated respectively, so that the load of each row of rollers can be accurately determined and can bear various loads at the same time. It is one of the four products with the largest bearing capacity. The axial and radial dimensions are large and the structure is firm. It is especially suitable for heavy machinery requiring larger diameter, such as bucket wheel excavator and wheel type lifting machine Heavy machinery, marine crane, ladle slewing and large tonnage truck crane and other machinery.

The single row cross roller slewing bearing is similar to the four point contact spherical slewing bearing, with only one row of rolling elements, which are short cylindrical rollers; the axes of adjacent rollers are arranged in a 90 ° cross; there are two raceways in the inner and outer rings, and the raceway section is linear. Half of the rollers bear the downward axial force and the half bear the upward axial force.

The single row four point contact ball slewing bearing has a row of steel balls as rolling element, and there is a single isolation block between the steel balls. The inner and outer rings are integral, and the steel balls are loaded through the filling holes. The ball is in contact with four points of raceway and can bear axial force, radial force and overturning moment at the same time.

These two kinds of slewing bearings have their own characteristics. As the contact angle between the roller and the roller of the slewing bearing is larger than that of the ball bearing, the contact angle between the roller and the ball bearing will be larger than that of the ball bearing. Therefore, considering that the vibration of the boom should be as small as possible, the cross roller slewing bearing should be preferred.

Three row roller slewing bearing is an important transmission component. In order to achieve relative rotation, it needs to bear a lot of force during the operation. With the wide use of various mechanical equipment, three row roller slewing bearing is the most important part of the equipment. Essential accessories are widely used in various construction machinery, medical machinery and industrial equipment, and have been highly recognized. The external gear of light series slewing bearing is an essential product in three row roller slewing bearing. If the equipment is worn during operation, it can be lubricated between multiple parts to reduce friction and tear. It is better to stop the equipment and conduct detailed inspection to enhance the operation of the whole mechanical equipment. Meanwhile

In order to prolong the service life of the three row roller slewing bearing in the machine, it is usually best to pay attention to the corrosion of the product to the corrosive product and take anti rust measures. Usually, clean the surface regularly and use the cleaning effect. It is better to keep the product surface dry at the same time, pay attention to the application of anti rust oil, if you encounter special circumstances, you can choose to use antirust oil. In fact, three row roller slewing bearing is a very good product. It is better not to touch it with hands when not in use, so as not to corrode the bracket.

Longwe Transmission slewing bearing team is committed to keep the spirit of continuous improvement and focus our strategy of strict quality control standards, quick response, prompt delivery and low price.We look forward to working on all of our customers’ growing demands. Our ability to optimize the bearing design for your specific needs is unparalleled and we will assist you throughout the design, manufacturing and implementation process.

Products type | 1.single – row four – point contact ball |

Special services | 1.slewing bearing design |

Business type | manufacturer,trading company |

Advantages | 1.ISO 9001:2008 certificate,12 years experience2.High qualified material,low MOQ,excellent quality,competitive prices, |

Material | 50Mn/42CrMo or as your requirements |

Package | 1.First lubricated, Second circled with plastic film,kraft paper,blue belt,then packaged inwooden case,last gathered in Wooden pallet.2 According to your requirements

|

Delivery time | 1.For general product , our delivery time need only 5 days is enough (goods in stock).2.If you have special technical requirements or need additional processing,we first rder need only 45 ys, if that is roller continuous order, our delivery time only need 35 ys.

|

Application fields | Mine machine, port hoisting machine, port oil transfer equipment onshore and offshorecrane,excavator,concrete machine,paper machine, plastic and rubber machine, weavemachine, steel plant, electronic power plant, wind power generator, other construction and industry machines or equipment.

|

We supplied high quality product & good service to every end user and valued distributors all over the world. We’ve enjoyed a very good reputation up to now.

Our manufacturing standard is according to machinery standard JB/T2300-2011, we also has been found the efficient Quality Management Systems(QMS) of ISO 9001:2015 and GB/T19001-2008. We devote ourselves to the R &D of customized slewing bearing with high precision,special purpose and requirements and has acquired certificate of China Classification Society .

If you have any questions, pls do not hesitate to contact us.

FAQ

1: How to order?

Please refer to the help under the single payment.

2.What are the shipping methods?

Ocean shipment to the port close to your city; Air shipment to the airport close to your company; Door to door service by international express.

3.When can I get the price?

We usually quote within 12 hours after we get your inquiry. If urgent to get the price, please call us or tell us by email , we will regard your inquiry priority.

4.You are a trader or a manufacturer?

We are an industry and trade integration business, our factory located on Xuzhou City.

5.How about the payment terms?

We usually accept T/T or L/Cat sight . other terms also could be negotiated.

6.What is your minimum order?

It depends on what you are buying. Normally, our minimum order is 1pcs.

7.What is your delivery time?

If there are any parts in stock , our delivery time is only 3-7 days. If our standard model,the delivery time is around 25 days,if non-standard model,the delivery time is 38~45 days.

Reviews

There are no reviews yet.