There are several types of AGVs. These include:

Automated carts – The simplest kind of AGV with minimal features for lowest cost implementation.

Unit load AGVs – Individual vehicles that transport loads (typically pallets, bins, carts or bundles) on forks or on the AGV’s deck. Roll-handling AGVs specifically handle heavy rolls of steel or paper.

Tugger AGVs – Powered units pulling a series of non-motorized trailers that each carries a load.

Automated forklift AGVs – An existing forklift truck whose controls have been converted to allow unmanned operation

| products discription | |||

|---|---|---|---|

| Model Number: | 110.09.210 | Brand name | longwei |

| Production Experience | Since 2004 | Applicable Industries: | Insdustry robot |

| Rolling-Element Number | Single-Row | Gear Options: | without gear |

| Material | 50Mn/42CrMo/Customized | Seals Type: | as Requirement |

| Advantage | low Noise,low vibration ,High Precesio | CERTIFICATE: | ISO9001:2008/SGS |

| Bore Diameter | 140 mm | Outside Diameter | 200mm |

| Roller Type | Deep Groove Raceway | RACEWAY hardness: | 55HRC -62HRC |

| Products Name | single row Cross roller none teeth slewing bearing | Service: | OEM Service.Design Service |

| Net Weight : | 2.96kgs | Material of Rolling element: | GCR15 |

| Warranty Period | 1 year | Testing | In house or third party |

| Origin | CHINA | MOQ | 1 SET |

| Height | 25mm | H.S. Code | 848250900 |

| Packaging Details | 1. Industrial Neutral Packing 2. Package as your requirements.3. Small size Bearings:Plastic vacuum packaging bag+Paper Box/Neutral Carton 4.Large size Bearings:Plastic film+pergamyn paper+Roll tape+Wooden Box | Precision | P5 P4 P2 |

Automatic Guided Vehicle application:

Assembly Line

AssemblyTBX1_200pxLow profile and custom designed vehicles provide improved ergonomics and are designed to operate as the assembly production line.

Conveyor Vehicles

Dual-Inline-ConveyorTransbotics automatic guided conveyor style vehicles come in various sizes and load capacities. This allows the AGV to pickup and deliver many types of material such as pallets, drums, skidded items, totes and boxes from standard conveyor lines, palletizing cells, finished good lines and deliver to stretch wrappers, unload stations, shipping or warehousing.

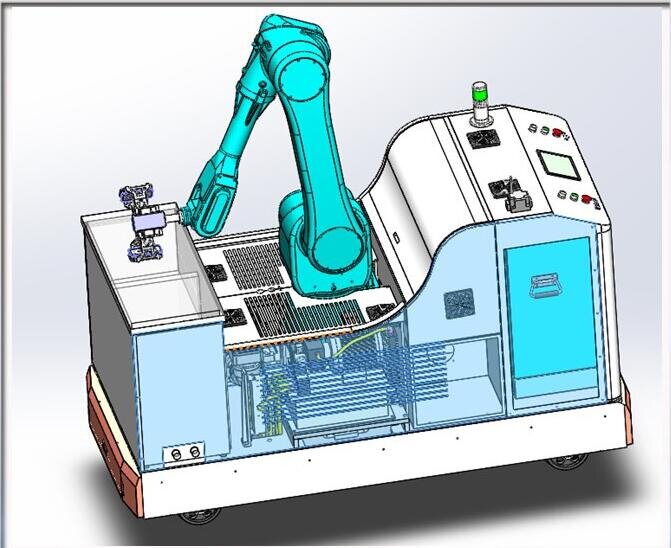

Custom Engineered AGV Vehicles

Custom-Conveyor-Lift-DeckWe offer standard as well as Tailor-Made™ AGV Systems.

Heavy Load Transport

liftdeckAGV_200pxHeavy capacity vehicles provide safe, reliable movement of large or cumbersome loads.

Fork Lift & Roll Handling Vehicles

agvforklifticonTransbotics Forklift vehicles are designed to replace manually driven forklift trucks and pallet hand trucks. The vehicles can move a variety of items including pallets and skidded items with various load weights. Fork Style AGVs are used in almost every industry, including aerospace & defense, automotive and tier one supplier, textiles, ceramics, chemical processing, food & beverage, warehousing, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

Tuggers

TuggerTuggers are offered for light or heavy duty applications. Tugger AGVs are used in almost every industry, including aerospace & defense, automotive and tier one supplier, textiles, ceramics, chemical processing, food & beverage, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

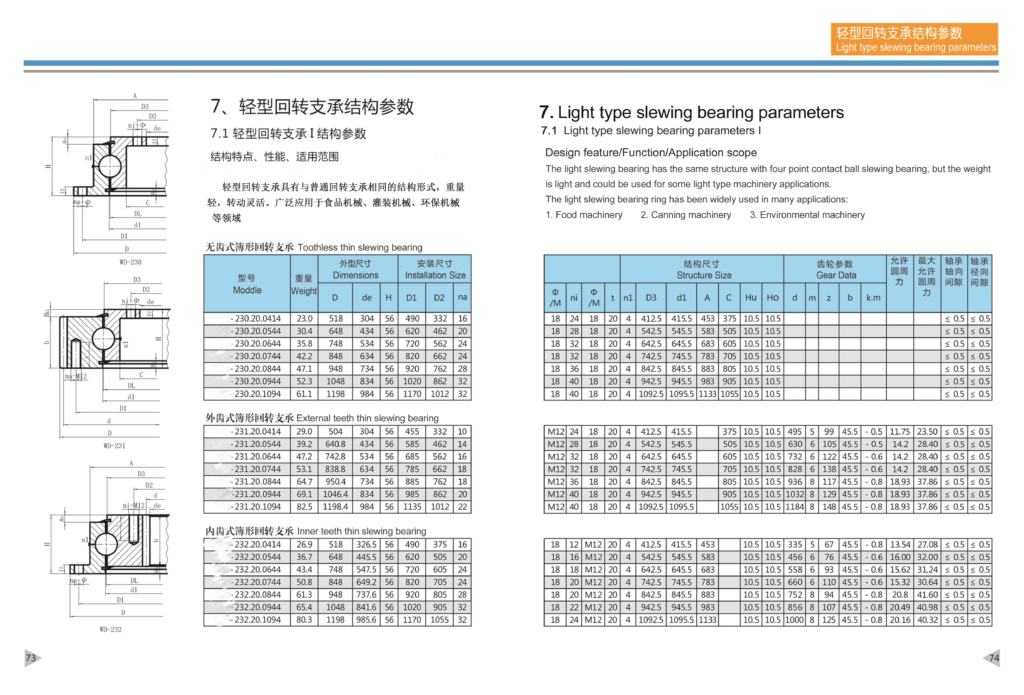

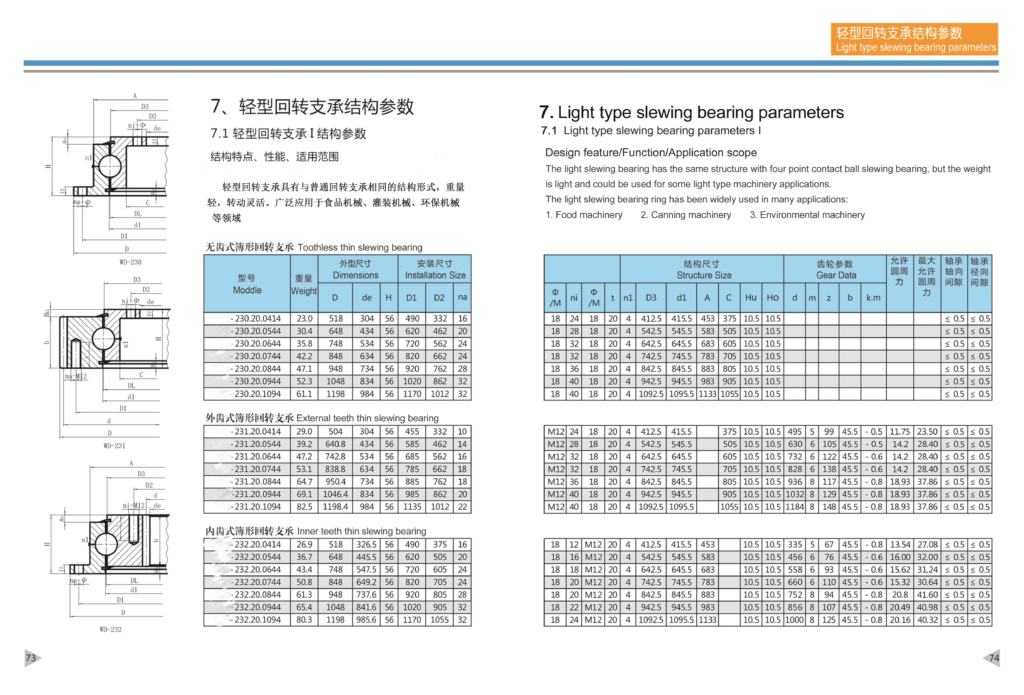

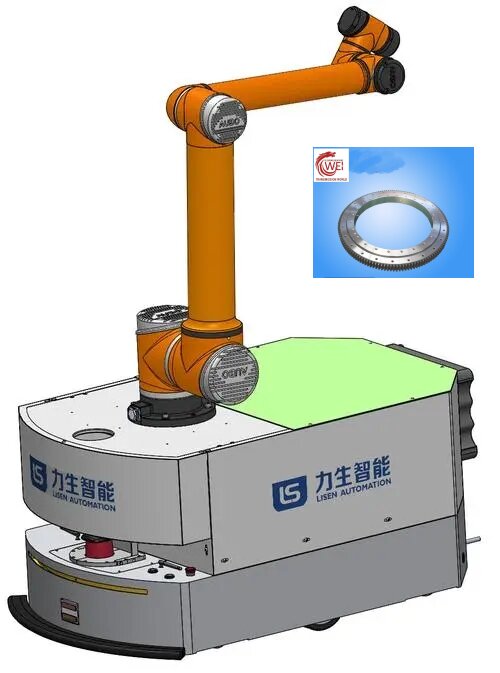

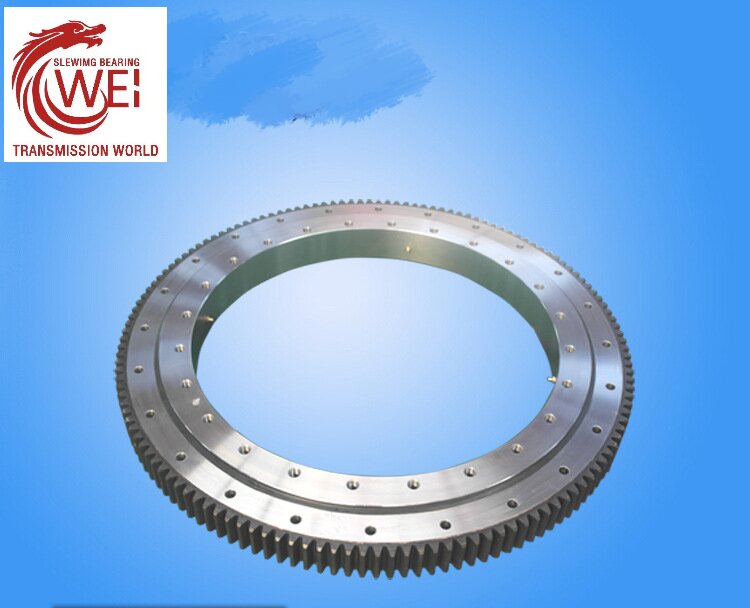

Automated guided vehicle slewing bearings

Slewing bearings comprise an inner ring and an outer ring, one of which usually incorporates a gear. Together with attachment holes in both rings, they enable an optimized power transmission with a simple and quick connection between adjacent machine components. The bearing raceways, in conjunction with the rolling elements and cages or spacers, are designed to accommodate loads acting singly or in combination, and in any direction.

monton application engineering service

Selecting the appropriate slewing bearing can be a challenge, particularly if there are stringent technical, reliability or economic demands. In these cases, for example, monton application engineering service can provide advanced calculations and simulations utilizing state-of-the-art analyse methods to optimize and validate the best design to meet the customer requirements.

Automated guided vehicle crossed roller bearings

Mounting holed type, high rigidity crossed roller bearings

High rigidity crossed roller bearings feature solid, one-piece construction for high accuracy.

Standard crossed roller bearings

Slim crossed roller bearings

Super slim crossed roller bearings

Crossed roller bearings provide more accuracy, rigidity, and weight-bearing capacity for linear motion than other commonly used friction-reducing devices such as ball bearings. And unlike ball bearings, they can support moment loads, radial forces or tilting loads. This lets one crossed roller bearing replace more than one ball bearing, thus saving the space required by ball bearings, lowering the associated material costs.

Crossed roller bearings are preferred for high-precision linear-motion applications with relatively short linear movements that require smooth motion. They are also durable, lasting 150 million cycles, even for linear-motion applications with high levels of acceleration and deceleration when using 2 to 12-mm rollers and 30 to 600-mm lengths.

They can be found in medical and lab equipment, machine tools, semiconductor processing, clean rooms, vacuum environments, material handling, and automation machinery. And as technology becomes more demanding, requiring greater and greater precision, crossed roller bearings will also become more common.

What Is an Automatic Guided Vehicle?

There are several types of AGVs. These include:

Automated carts – The simplest kind of AGV with minimal features for lowest cost implementation.

Unit load AGVs – Individual vehicles that transport loads (typically pallets, bins, carts or bundles) on forks or on the AGV’s deck. Roll-handling AGVs specifically handle heavy rolls of steel or paper.

Tugger AGVs – Powered units pulling a series of non-motorized trailers that each carries a load.

Automated forklift AGVs – An existing forklift truck whose controls have been converted to allow unmanned operation

| products discription | |||

|---|---|---|---|

| Model Number: | 110.09.210 | Brand name | longwei |

| Production Experience | Since 2004 | Applicable Industries: | Insdustry robot |

| Rolling-Element Number | Single-Row | Gear Options: | without gear |

| Material | 50Mn/42CrMo/Customized | Seals Type: | as Requirement |

| Advantage | low Noise,low vibration ,High Precesio | CERTIFICATE: | ISO9001:2008/SGS |

| Bore Diameter | 140 mm | Outside Diameter | 200mm |

| Roller Type | Deep Groove Raceway | RACEWAY hardness: | 55HRC -62HRC |

| Products Name | single row Cross roller none teeth slewing bearing | Service: | OEM Service.Design Service |

| Net Weight : | 2.96kgs | Material of Rolling element: | GCR15 |

| Warranty Period | 1 year | Testing | In house or third party |

| Origin | CHINA | MOQ | 1 SET |

| Height | 25mm | H.S. Code | 848250900 |

| Packaging Details | 1. Industrial Neutral Packing 2. Package as your requirements.3. Small size Bearings:Plastic vacuum packaging bag+Paper Box/Neutral Carton 4.Large size Bearings:Plastic film+pergamyn paper+Roll tape+Wooden Box | Precision | P5 P4 P2 |

Automatic Guided Vehicle application:

Assembly Line

AssemblyTBX1_200pxLow profile and custom designed vehicles provide improved ergonomics and are designed to operate as the assembly production line.

Conveyor Vehicles

Dual-Inline-ConveyorTransbotics automatic guided conveyor style vehicles come in various sizes and load capacities. This allows the AGV to pickup and deliver many types of material such as pallets, drums, skidded items, totes and boxes from standard conveyor lines, palletizing cells, finished good lines and deliver to stretch wrappers, unload stations, shipping or warehousing.

Custom Engineered AGV Vehicles

Custom-Conveyor-Lift-DeckWe offer standard as well as Tailor-Made™ AGV Systems.

Heavy Load Transport

liftdeckAGV_200pxHeavy capacity vehicles provide safe, reliable movement of large or cumbersome loads.

Fork Lift & Roll Handling Vehicles

agvforklifticonTransbotics Forklift vehicles are designed to replace manually driven forklift trucks and pallet hand trucks. The vehicles can move a variety of items including pallets and skidded items with various load weights. Fork Style AGVs are used in almost every industry, including aerospace & defense, automotive and tier one supplier, textiles, ceramics, chemical processing, food & beverage, warehousing, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

Tuggers

TuggerTuggers are offered for light or heavy duty applications. Tugger AGVs are used in almost every industry, including aerospace & defense, automotive and tier one supplier, textiles, ceramics, chemical processing, food & beverage, newsprint & publishing, microelectronics, plastics, primary metals and recycling.

Automated guided vehicle slewing bearings

Slewing bearings comprise an inner ring and an outer ring, one of which usually incorporates a gear. Together with attachment holes in both rings, they enable an optimized power transmission with a simple and quick connection between adjacent machine components. The bearing raceways, in conjunction with the rolling elements and cages or spacers, are designed to accommodate loads acting singly or in combination, and in any direction.

monton application engineering service

Selecting the appropriate slewing bearing can be a challenge, particularly if there are stringent technical, reliability or economic demands. In these cases, for example, monton application engineering service can provide advanced calculations and simulations utilizing state-of-the-art analyse methods to optimize and validate the best design to meet the customer requirements.

Automated guided vehicle crossed roller bearings

Mounting holed type, high rigidity crossed roller bearings

High rigidity crossed roller bearings feature solid, one-piece construction for high accuracy.

Standard crossed roller bearings

Slim crossed roller bearings

Super slim crossed roller bearings

Crossed roller bearings provide more accuracy, rigidity, and weight-bearing capacity for linear motion than other commonly used friction-reducing devices such as ball bearings. And unlike ball bearings, they can support moment loads, radial forces or tilting loads. This lets one crossed roller bearing replace more than one ball bearing, thus saving the space required by ball bearings, lowering the associated material costs.

Crossed roller bearings are preferred for high-precision linear-motion applications with relatively short linear movements that require smooth motion. They are also durable, lasting 150 million cycles, even for linear-motion applications with high levels of acceleration and deceleration when using 2 to 12-mm rollers and 30 to 600-mm lengths.

They can be found in medical and lab equipment, machine tools, semiconductor processing, clean rooms, vacuum environments, material handling, and automation machinery. And as technology becomes more demanding, requiring greater and greater precision, crossed roller bearings will also become more common.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.