| Products discription | |||||

|---|---|---|---|---|---|

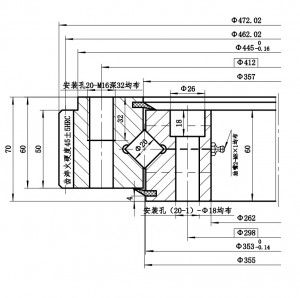

| Model Number: | 110.32.1250 | Brand name | longwei | ||

| Production Experience | Since 2004 | Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Construction works , Energy & Mining, Food & Beverage Shops,Military, | ||

| Feature: | Single Row Crossed Roller | Gear Options: | without Gear | ||

| Material: | 50Mn/42CrMo/Customized | Seals Type: | NBR or as requirement | ||

| MOQ | 1 set | CERTIFICATE: | ISO9001:2008/SGS | ||

| Bore Diameter | 1110 mm | Outside Diameter | 1390mm | ||

| Operating tempereature: | -30°C +70°C | Hardness: | 207-262HB | ||

| Product Name: | High Precision Single Row Crossed Roller without Gear Slewing Ring | Service: | OEM Service.Design Service | ||

| Net Weight : | 350 | Rolling element: | Roller & Spacer | ||

| Warranty Period | 1 year | Testing | In house or third party | ||

| Key Word | High Precision Small Diameter Slewing Bearing | Size | Standard OR Customized | ||

| Height | 91mm | H.S. Code | 848210900 | ||

| Packaging Details | 1.Filling with rust-proof oil 2.packing with protective layers 3.Fixed in the plywood 4.Packaging terms:Plywood case/ Pallet/Steel frame | Product Type: | Single Row Crossed Roller |

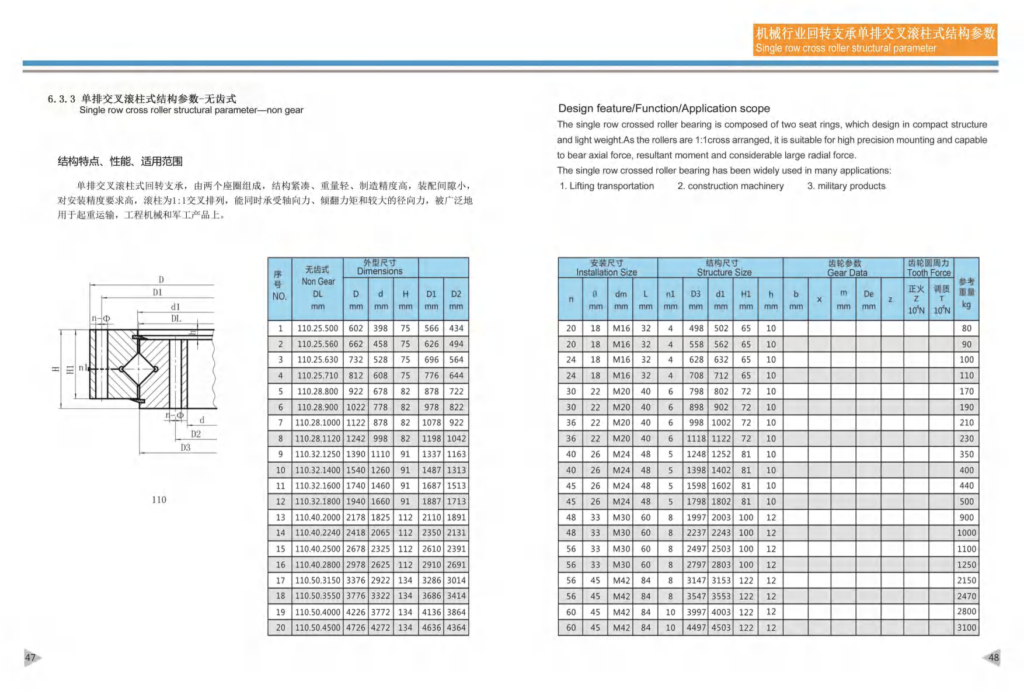

Single Row Crossed Roller Slewing Bearing ( 11 series )

The Single Row Crossed Roller Slewing Bearing is composed of two seat-rings. It features compact in design, light in weight,high precision and small fitting clearance.

As the rollers are 1:1cross arranged,it is suitable for high precision mounting and capable to bear axial force,resultant moment and considerable large radial force.

| Naming of slewing bearing |

|---|

| 0 1 2 . 40. 1000 |

| | | | | | |

| | | | | | |

| | | | | |_ _ _ _ mm diameter of rolling center |

| | | | | |

| | | | |_ _ _ _ __ _ mm diameter of rolling element |

| | | | |

| | | | |

| | | |_ _ _ _ __ _ _ _ _ Driving type code |

| | | 0--No gears |

| | | 1--External gear with small module |

| | | 2--External gear with big module |

| | | 3--Internal gear with small module |

| | | 4--Internal gear with big module |

| | | |

- If you are a customer buying standard products, please consult customer service for detailed drawings

- .If you need customized products, please send the drawing to me in time, and I will make the quotation and production time for you.

- Please feel free to contact me if you have any other requirements. I will reply to you in time.

Our Services & Strength

1.Raw material from reliable suppliers;

2.Production process is in strict accordance with ISO9001 Quality Management System .

3.Strict in-process quality control and 100% finished product inspection before delivery;

4.Third party product inspections are acceptable upon customer request.

5.Adoption of standardized product design process and APQP, PPAP, FEMA for application analysis.

- Manufacturer of producing bearing for about twenty years.

7. Advanced mechanical equipment and strict quality control team.

8. Efficient production speed and on-time delivery service.

9. Accept standard and non-standard production.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.