Tower cranes are now widely used in project engineering. It is made by slewing tower system, slewing mechanism, down support and slewing bearing ect. Among them, the slewing ring is the key core part of the tower crane structure.

The slewing bearing used by the tower crane requires smooth operation and high safety performance. Selecting the appropriate slewing bearing can effectively achieve the effect of stability and safety, and prolong the service life.

Working principle of slewing bearing of tower crane

- Tower crane implements tower slewing mechanism, which relies on boom slewing to ensure its working coverage.

- The rotation movement is produced by the upper and lower slewing bearings which are respectively installed on the inner and outer rings of the slewing bearing, and the pinion is driven by the slewing mechanism. The pinion is meshed with the big gear of the slewing bearing to drive the upper slewing bearing to move relative to the lower slewing bearing.

- Generally, the slewing mechanism is composed of slewing motor, hydraulic coupling, planetary reducer and pinion. In addition, according to the needs, the slewing mechanism is equipped with limit torque limiter, slewing buffer device, slewing limiter and other safety devices.

- In order to prevent the boom from sliding under the action of strong wind, the slewing mechanism is equipped with a stopper. But in the non working state, the slewing mechanism should allow the boom to rotate freely with the wind.

Generally, light and medium tower cranes are only equipped with one set of slewing mechanism. The heavy tower crane is equipped with two sets of slewing mechanism. Super heavy tower crane is equipped with 3 ~ 4 sets of slewing mechanism according to different lifting capacity and moment of inertia. The stable speed control system and pole changing motor are adopted, which can start and brake smoothly.

We focus and control every production detail,Only for the delivery of good products to customers.

The material of the slewing bearing are generally high alloy-structural steels,such as 42CrMo,50Mn.

The material of rolling body is GCr15 and it is purchased from domestic suppliers with highest quality.

Product available including: Single and Double Row Ball, Three Row Roller, Cross Roller Sealed and Unsealed Internal Geared, External Geared and Non-Geared Clearance or Preloaded.

Note:

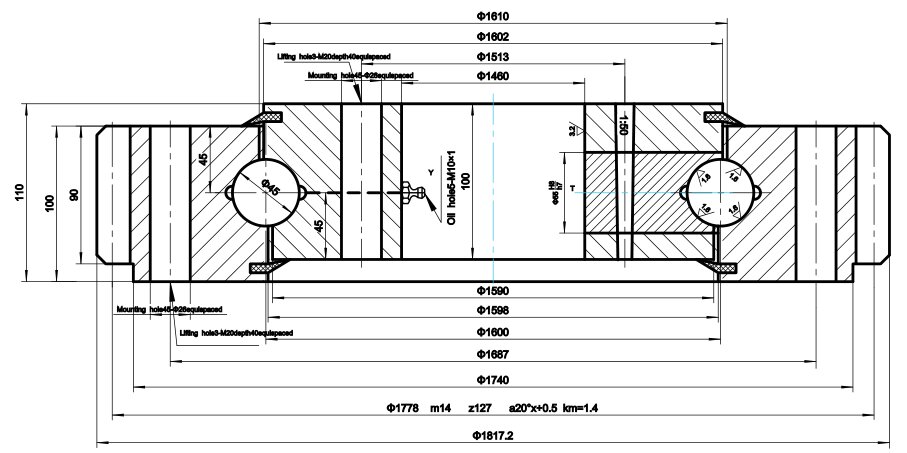

1. n1 is the nos of lubricating holes.Oil cup M10×1JB/T7940.1~JB/T7940.2.The Oil nipple’s location can be change according to the user’s application.

2. n-φcan change to tapped hole,the diameter of tapped hole is M,depth is 2M.

3. The tangential tooth force in the form is the max tooth force,the nominal tangential tooth force is 1/2 of the max one.

4. “K” is addendum reduction coefficient.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.