Application principle of slewing bearing

The motor or reducer drives the pinion to rotate, and the pinion drives the slewing bearing to rotate, so that the upper mechanism connected to it rotates accordingly.

| Plane deviation of mounting bracket P (mm) | ||||

|---|---|---|---|---|

| Raceway center diameter | Plane deviation of mounting bracket P (mm) | |||

| DL(mm) | single row four ball | double row ball | cross roller | |

| ~1000 | 0.15 | 0.2 | 0.1 | |

| >1000~1500 | 0.19 | 0.25 | 0.12 | |

| >1500~2000 | 0.22 | 0.3 | 0.15 | |

| >2000~2500 | 0.25 | 0.35 | 0.17 | |

| >2500~4000 | 0.3 | 0.4 | 0.2 | |

| >4000~6000 | 0.4 | 0.5 | 0.3 | |

| >6000~8000 | 0.5 | 0.6 | 0.4 | |

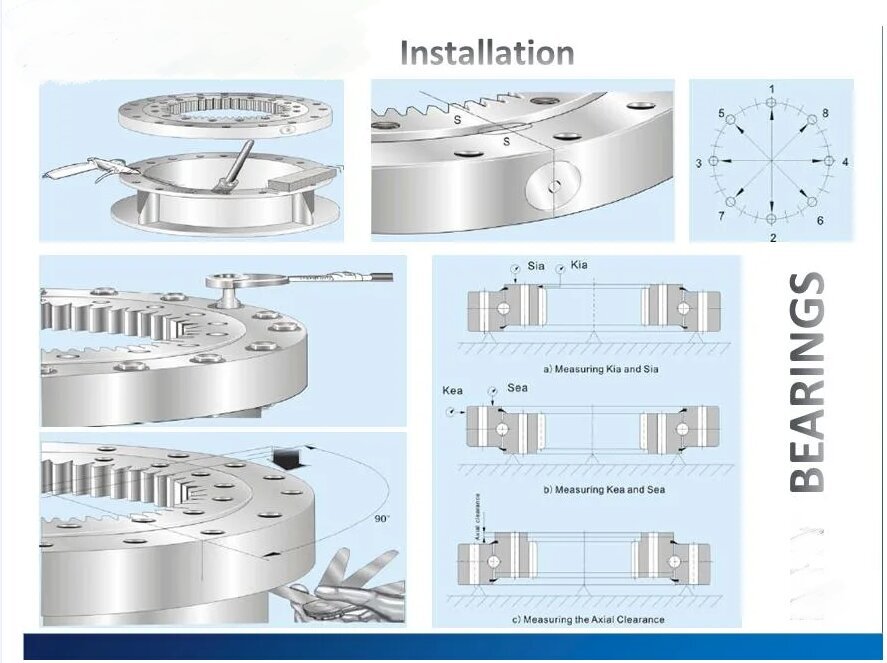

INSTALLATION OF Longwei transmission SLEWING BEARINGS

Preparation:

Make sure that the model is correct and slewing bearing isn’t damaged during transportation.

2. Check the appearance and rotational state of the bearing, such as rotational precision clearance, rotating flexibility, seals position, lubrication grease etc.

3. The installation datum plane and bracket installing plane should be clean, grease, burr, paint and other foreign body should be wiped off.

Installation:

1. The screws in the installing plane should be fit with the mounting holes in the slewing bearing

2. The slewing bearing has a soft zone marked with an “s” on the upper surface, when installing the bearing, it is important to ensure that this area is placed in a non-load or infrequent load zone.

3. When the bearing is placed on the supporting frame work it is important to check the interface between these two surfaces. This check should be carried out with the insertion of feel gauges between the two surfaces. If a gap should exist then it is recommended to plane/resurface the effective area so as to remove the gap.

4. Install slewing bearing with high strength screws, and choose appropriate strength bolts. All bolts are required to be tightened evenly. The sequence of this tightening process is shown in Pic. Welding of bearing is not allowed, in the event of welding any adjacent parts, heat transfer shall be avoided so as to cause the bearing to become deformed or change the hardness.

5. After installation, the bearing should be rotated to check for smooth operation and any emission of unusual noise. If either of the aforementioned are noted, then the bearing should be adjusted to eliminate them. The teeth of the largest run-out are coated with green paint.

Why choose Longwei transmission slewing bearings

A pioneer in slewing bearing field, rich experience, can do design, produce, mounting guide

Small order accepted

ISO certified company

Variorum models

7*24hours hotline to help you with your cranes

Strict quality control system to ensure quality for slewing bearing

Longwei transimission Slewing Bearing Types

slewing bearings can be divided into the following types as per their structures:

single row four point contact ball slewing bearing,

single row cross roller slewing bearing,

double row different ball diameter slewing bearing,

three row cylindrical roller slewing bearing and roller/ball combination slewing bearing.

And all these types of slewing bearings can be further divided into bearings without gears, bearings with external gears and bearings with internal gears.

Detailed description of these types slewing bearingsSingle row four point contact ball slewing bearings

This kind of slewing bearings can support high dynamic loads, transmitting axial and radial forces simultaneously as well as the resulting tilting moments. Applications of this kind of bearings are hoisting, mechanical handling and general mechanical engineering etc.

Single row cross roller slewing bearings

This kind of bearings can support combinations of large radial force, medium axial force and tilting moment with small or zero clearance. Main applications of this kind of bearings are hoisting and mechanical handling and general mechanical engineering etc.

Double row different ball diameter slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Triple row cylindrical roller slewing bearings

This kind of bearings has high load carrying capacity. Under same loads, this kind of bearings has much smaller diameters which can make the installation much compact, as different kinds of loads are supported by different races and rollers. Main applications of this kind of bearings are hoisting, mechanical handling, mining and materials handling, offshore technology and general mechanical engineering etc.

Roller/ball combination slewing bearings

This kind of bearings can support high axial load and low tilting moments. Usually they are large diameter slewing bearings. Applications of this kind of bearings are mining and materials handling etc.

About Longwei

Provide you with customized industry solutions

More than ten years of production experience, strict quality control can be the guarantee of the best solution in the industry.

China’s leading supplier of slewing bearings, its products have passed ISO 9001 and CAPE certification, and has a number of product patents.

The flexibility of our dialogue and approach with our clients is combined with responsive design and development innovation to ensure exceptional delivery.

FAQ

Do you have any questions about our slewing bearing? Maybe you can find the answer below. If the answer below does not solve your problem, please contact us and our engineer will answer it for you.

1. Where is your slewing bearing manufactured?

Our slewing bearings are all manufactured in China. We not only have the ability to design and produce slewing bearings but the quality can also be guaranteed. At the same time, our slewing-bearing price is more favorable.

2. I don’t know which slewing bearing to use, can you choose for me?

Yes, of course, Each model has a parameter list on the website. You can choose the suitable slewing bearing according to these parameter lists. If you don’t know how to choose, you can get in touch with us and our engineers will work with you to choose the suitable product. We can also design a new slewing bearing solution for you according to your equipment.

3. Can I get your product catalog?

You can get our product catalog in the download or contact us, we will send the product catalog to you by email or other ways.

4. Can you customize products?

Yes, we can. Our engineers have very rich experience in slewing bearing design. On the customized slewing bearing page, you can see some special customized products designed by our engineers. These design solutions meet the special needs of many customers. Our engineers can also work with you to design a new slewing bearing.

5. Can you provide accessories?

Yes, we can provide matching spare parts such as motors, hydraulic motors, and encoders that are compatible with slewing bearings.

6. Can you provide a 3D model?

Yes. All our slewing bearings have 3D models, you can contact us to get them. At the same time, we can also provide CAD files and PDF files.

7. How long is your slewing bearing warranty period?

Our slewing bearing warranty time is 12 months. When you install, use, and store the slewing bearing, please refer to the slewing bearing instruction manual.

8. Can you choose the color of your slewing bearing?

Yes. Our slewing bearing is available in many colors. If you have special requirements, please tell our sales engineers, we are happy to provide services for you.

Reviews

There are no reviews yet.